Q-Connect - Analyze. Optimize. Profitize.

Optimize your production with centralized real-time data.

Streamline your manufacturing processes by leveraging centralized real-time production data for smarter decision-making and increased efficiency. Whether you're operating a single machine or managing complex systems across multiple locations – Q-Connect gives you full visibility into machine status and performance anytime, anywhere.

And the best part: your data can be stored locally, without relying on the cloud – giving you full control over your infrastructure and data security.

Hear from our customer

What can you expect?

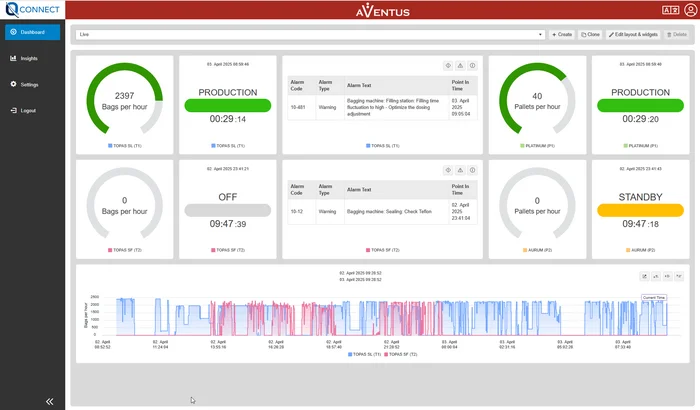

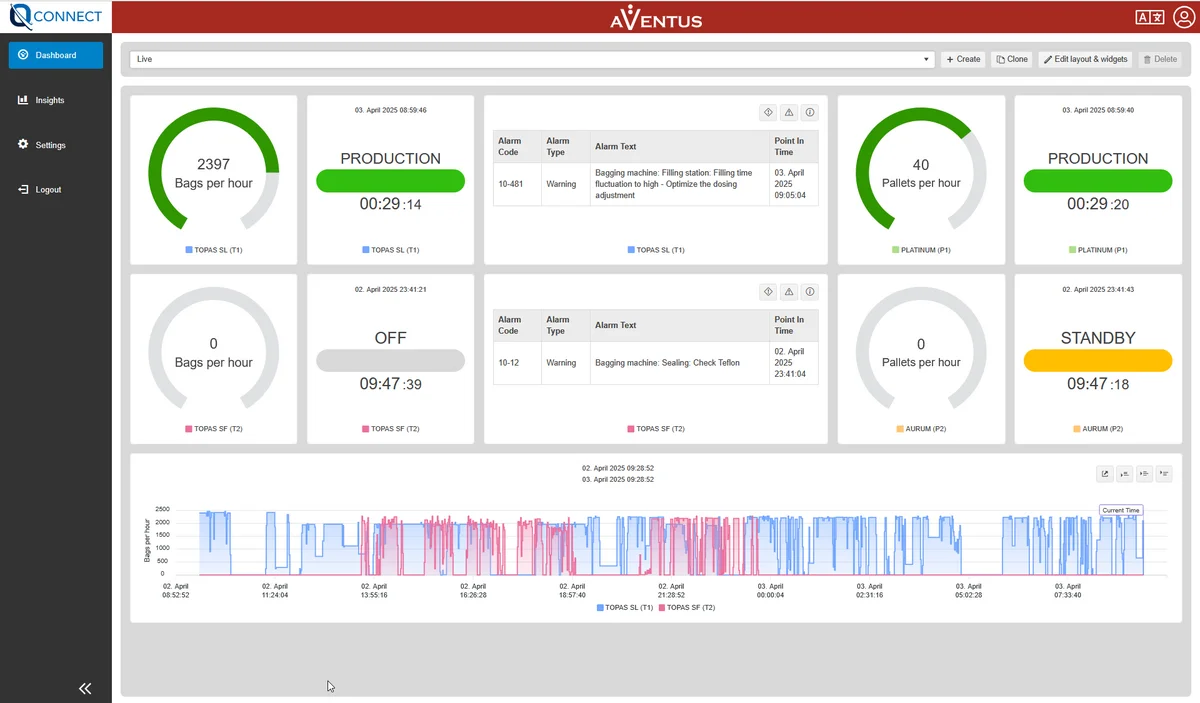

Gain a comprehensive overview of your machine status, current production performance, and error messages – all in real time.

Our solution empowers you to capture critical information instantly, respond proactively, and sustainably boost your manufacturing efficiency. With intuitive visualizations of key metrics, you stay in control at all times – transparent, reliable, and user-friendly.

Unlock the full potential of your production line.

Higher productivity. Reduced downtime. Future-proof manufacturing.

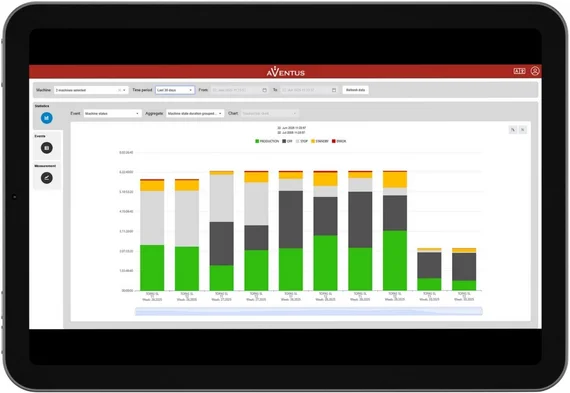

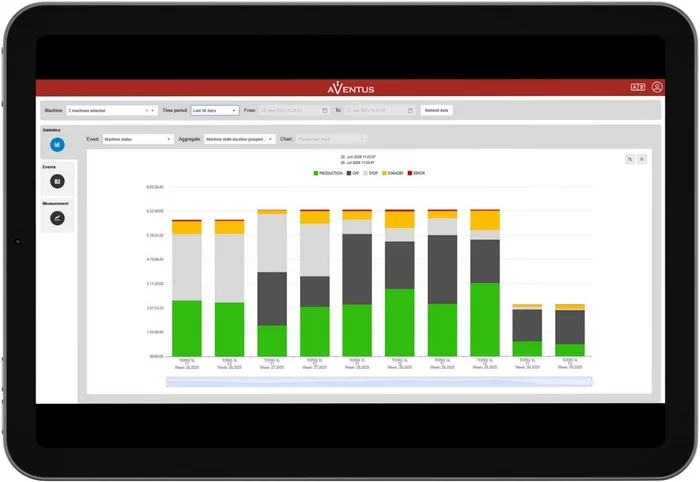

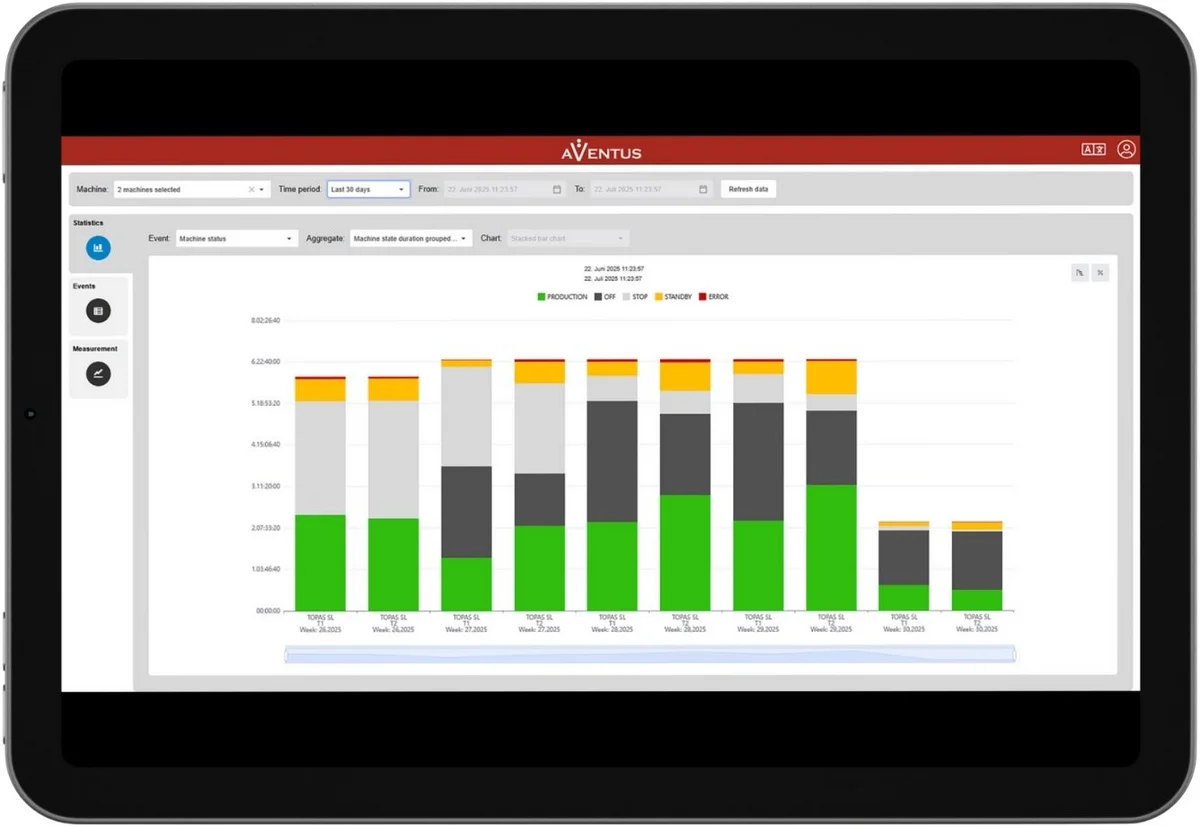

With our live machine status monitoring solution, you gain full clarity on your production conditions – anytime and across all locations. By continuously analyzing operating states, utilization, and disruptions, potential bottlenecks can be identified early and resolved proactively.

This helps you avoid unplanned downtime, improve production planning, and increase overall manufacturing performance. The transparent visualization of all relevant machine data enables fast decision-making and proactive process control.

More visibility. Less downtime. Greater efficiency.

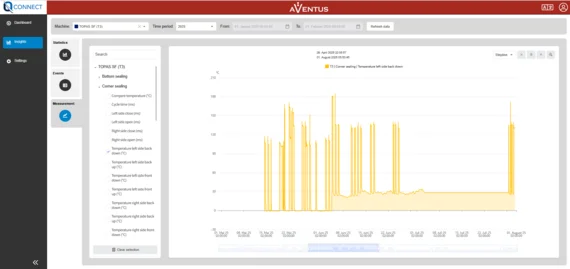

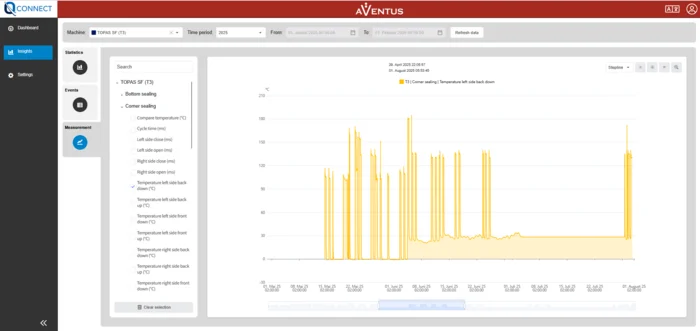

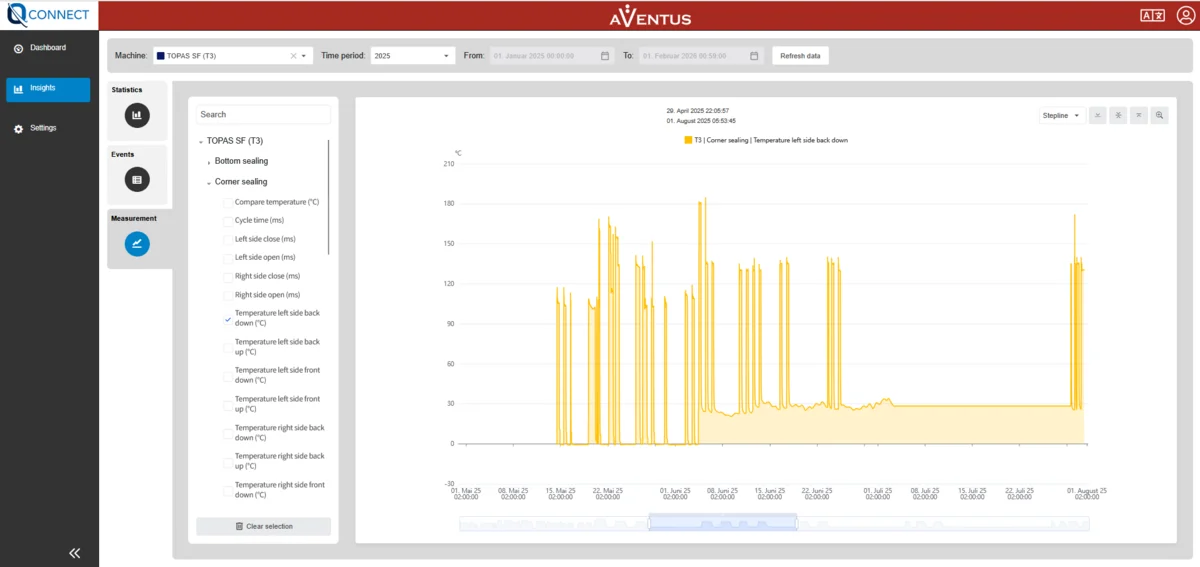

Keep your production parameters in view at all times: Q-Connect enables continuous acquisition and monitoring of key metrics such as temperature, speed, pressure, and other relevant process values – clearly and directly.

By evaluating this data in real time, you can instantly detect deviations, optimize your processes with precision, and ensure consistently high product quality. Transparent data visualization supports fast, data-driven decisions and helps you sustainably improve your production.

More control. More quality.

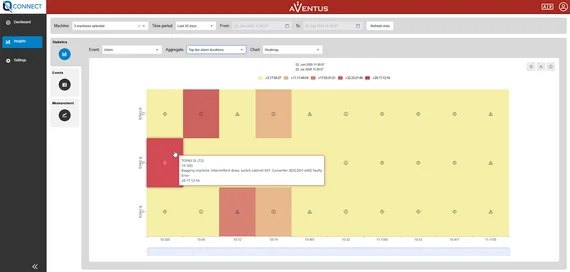

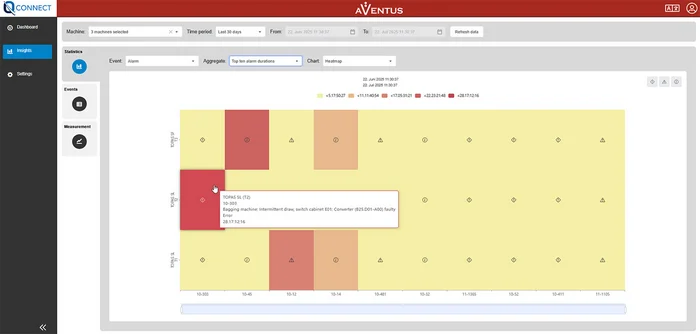

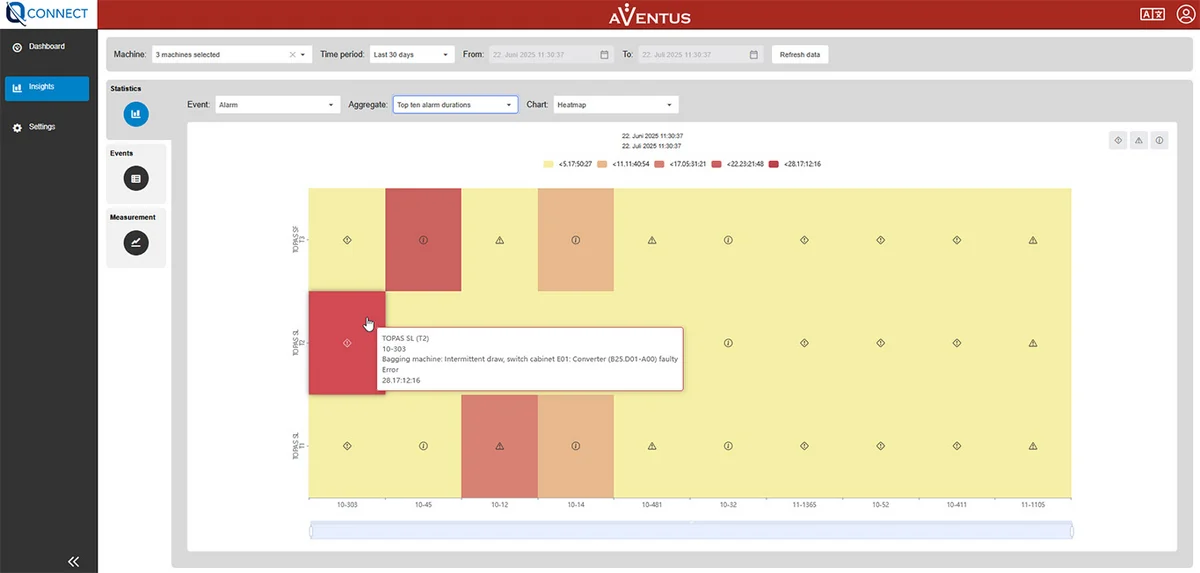

Q-Connect helps you not only detect faults in your production but also evaluate them effectively. By systematically capturing and analyzing error messages, you can quickly identify which issues occur most frequently and which lead to the highest downtime.

This transparency enables you to take targeted action to eliminate recurring problems, stabilize processes, and sustainably increase the availability of your equipment. Turn data into actionable improvements – for smooth and high-performance production.

Less downtime. More productivity. Smarter decisions.